Manual material handling remains one of the leading causes of workplace injuries across manufacturing and logistics facilities worldwide. When workers repeatedly lift, carry, and move heavy totes between workstations, they face significant risks of musculoskeletal disorders, back injuries, and repetitive strain injuries. These injuries not only impact employee well-being but also result in costly workers’ compensation claims, reduced productivity, and increased absenteeism.

Fortunately, modern conveyor automation offers proven alternatives that eliminate manual handling risks while simultaneously improving operational efficiency. This comprehensive guide explores the safest, most effective solutions for moving totes between workstations—from basic conveyor systems to advanced pallet automation.

The Hidden Costs of Manual Tote Handling

Before exploring solutions, it’s important to understand the full impact of manual material handling in your facility:

Safety Risks

- Musculoskeletal disorders (MSDs) account for 33% of all workplace injuries, with manual handling being the primary cause

- Back injuries from lifting heavy totes can result in long-term disability and chronic pain

- Repetitive strain injuries develop over time from continuous lifting and carrying

- Slip, trip, and fall hazards increase when workers carry loads that obstruct their vision

Operational Costs

- Workers’ compensation claims average thousands of dollars per incident

- Lost productivity from injured employees and temporary replacements

- Decreased efficiency as workers fatigue throughout their shifts

- Higher turnover rates due to physically demanding work conditions

Regulatory Compliance

Organizations must comply with OSHA standards and other workplace safety regulations regarding manual material handling. Failure to provide safer alternatives can result in citations, fines, and increased scrutiny from regulatory agencies.

Automated Conveyor Solutions: The Safer Alternative

Automated conveyor systems eliminate the need for manual tote handling by mechanically transporting materials between workstations. These solutions range from simple belt conveyors to sophisticated pallet systems, each offering distinct advantages based on your specific application requirements.

As outlined in this overview of automated tote storage benefits, automation not only reduces worker strain but also helps warehouses improve space utilization and workflow efficiency.

Belt Conveyor Systems

Belt conveyors provide a versatile, cost-effective solution for moving totes of various sizes across your facility. These systems feature continuous fabric or modular belts that smoothly transport materials without requiring worker intervention.

Key Advantages:

- Smooth product transfer reduces damage to sensitive items

- Quiet operation improves workplace ergonomics

- Multiple belt material options accommodate different load types and environments

- Easy integration with existing production lines

Dorner’s belt conveyor platforms offer solutions for every application scale. The 2200 Series low-profile conveyors handle loads up to 54 kg (120 lbs) while fitting into tight spaces between workstations. For heavier totes, the 3200 Series heavy-duty conveyors support loads up to 455 kg (1,000 lbs) with belt speeds reaching 182 m/min (600 ft/min).

Modular Belt Conveyors

When flexibility and durability are paramount, modular belt conveyors excel. These systems use interlocking plastic links instead of continuous fabric belts, offering superior longevity and simplified maintenance.

Key Features:

- Easy belt replacement—individual links can be swapped without removing the entire belt

- Open surface area facilitates air flow for cooling and drainage applications

- Curved configurations navigate around obstacles and corners

- Easy to clean, making them ideal for high particulate or sanitary applications

Flexible Chain Conveyors

For operations requiring complex routing between multiple workstations, flexible chain conveyors deliver unmatched versatility. These systems can navigate curves, inclines, and declines while maintaining positive product control.

Benefits:

- Multiple directional changes within a single system

- Low-profile design fits into confined spaces

- Capable of vertical lifts to change elevation between workstations

- Modular construction allows easy reconfiguration as needs change

Dorner’s FlexMove conveyor series offers aluminum and stainless steel options supporting loads from 150 kg to 300 kg. The flexible chain technology enables tight radius turns and steep inclines—ideal for maximizing floor space efficiency. Industry analysis of semi-automated conveyor solutions shows how even partial automation—such as flexible chain conveyors—can significantly reduce ergonomic risks while boosting productivity.

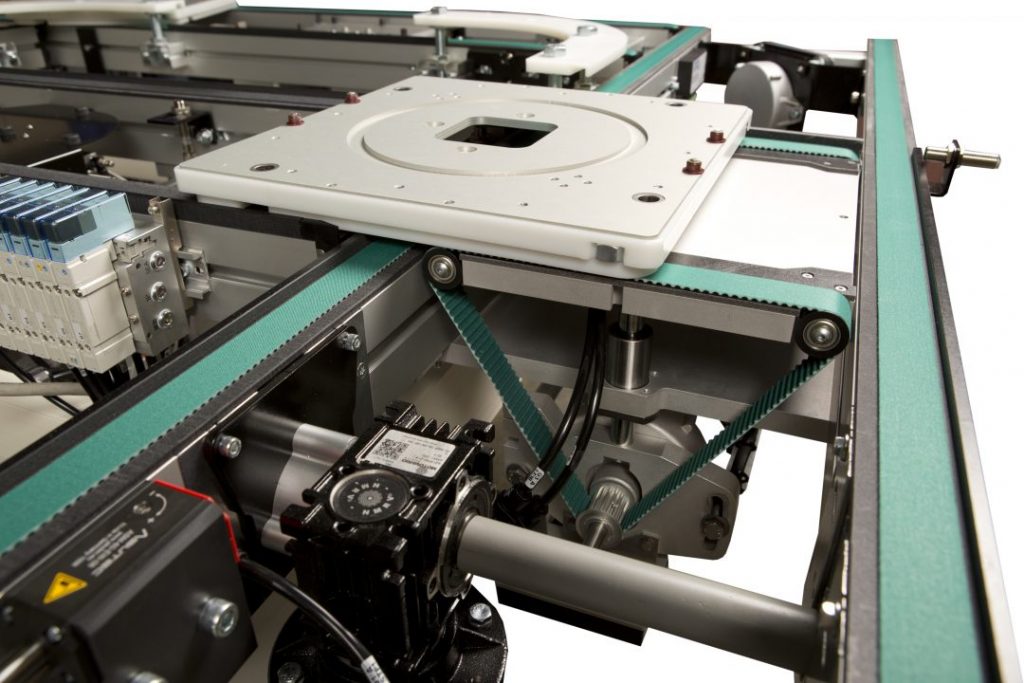

Pallet System Conveyors

When precise positioning and automated control are critical, pallet system conveyors provide the ultimate solution. These sophisticated systems transport products or totes on pallet carriers, offering sub-millimeter positioning accuracy for automated manufacturing processes.

Advanced Capabilities:

- Highly accurate product positioning within ± 0.5 mm

- Automated routing to multiple destinations

- Integration with robotics and automated assembly equipment

- Pin tracking system for intelligent pallet transport through curves and transfers

Forward-looking operations are also adopting tote management automation to combine conveyor transport with intelligent tracking, enabling precise routing and real-time inventory visibility.

Choosing the Right Solution for Your Application

Selecting the optimal conveyor system depends on several key factors:

Load Characteristics

- Weight: Range from miniature conveyors (6.8 kg capacity) to heavy-duty systems (114+ kg)

- Size: Tote dimensions determine required belt width and conveyor configuration

- Material: Product sensitivity influences belt surface selection (smooth, textured, or cleated)

Facility Layout

- Available space: Low-profile designs fit into constrained areas and between machinery

- Distance: Longer runs may require multiple conveyors or specialized configurations

- Elevation changes: LPZ (Z-frame) and helical designs handle vertical transitions smoothly

- Obstacles: Curved or flexible chain systems navigate around equipment

Process Requirements

- Speed: Production rates dictate required conveyor velocity

- Positioning accuracy: Automated processes may require high precision capabilities

- Environmental conditions: Food processing, cleanrooms, or harsh environments require specialized solutions

- Integration needs: Compatibility with existing equipment and control systems

Industry-Specific Considerations

Manufacturing & Industrial: Dorner’s industrial conveyor solutions provide robust tote handling for automotive, electronics, and general manufacturing. Heavy-duty frames withstand demanding production environments while maintaining precise product control.

Food Processing & Packaging: Sanitary stainless steel conveyors meet FDA and BISSC standards for food-grade applications. These systems feature quick-cleaning designs and corrosion-resistant construction for wash-down environments.

E-Commerce & Logistics: Distribution centers benefit from high-speed sortation and accumulation capabilities. The DCMove series offers economical belt conveyors specifically designed for parcel handling and order fulfillment operations.

Medical & Pharmaceutical: Cleanroom-certified conveyors maintain sterile environments while transporting sensitive products. ERT pallet systems provide the open-frame, belt-free design required for Class 4 cleanroom applications.

Implementation Best Practices

Successfully transitioning from manual handling to automated conveyors requires careful planning and execution:

1. Conduct a Thorough Assessment

- Map current material flow and identify bottlenecks

- Document all tote specifications (size, weight, frequency)

- Measure available floor space and clearances

- Evaluate power and control infrastructure

2. Engage Experienced Partners

Work with conveyor specialists who understand your industry’s unique challenges. Dorner’s application engineers provide comprehensive support from initial concept through installation and training.

3. Plan for Integration

- Ensure compatibility with existing equipment and controls

- Consider future expansion and scalability needs

- Develop contingency plans for maintenance and downtime

- Establish clear performance metrics and ROI targets

4. Train Your Team

Proper training maximizes system effectiveness and safety:

- Operation procedures and best practices

- Basic troubleshooting and maintenance

- Safety protocols and emergency procedures

- Performance monitoring and optimization

Dorner offers comprehensive training services, including on-site instruction, online resources, and ongoing technical support.

Measuring Success: ROI and Performance Metrics

Track these key indicators to quantify the benefits of automated tote handling:

Safety Improvements

- Reduction in workplace injuries and workers’ compensation claims

- Decreased employee fatigue and absenteeism

- Improved compliance with safety regulations

- Enhanced worker satisfaction and retention

Operational Efficiency

- Increased throughput and production capacity

- Reduced labor costs and overtime

- Minimized product damage during transport

- Improved order accuracy and quality

Financial Returns

Most facilities achieve ROI within 12-24 months through:

- Lower workers’ compensation insurance premiums

- Reduced labor costs and temporary staffing needs

- Decreased product damage and rework expenses

- Improved production capacity and revenue potential

Maintenance and Long-Term Reliability

Modern conveyor systems require minimal maintenance when properly specified and installed. Dorner conveyors feature:

Uptime-Enhancing Design:

- Sealed-for-life bearings eliminate frequent lubrication

- V-guided belting ensures consistent tracking

- Precision rack-and-pinion tensioning maintains optimal performance

- Modular construction enables quick component replacement

Comprehensive Support:

- 24/7 service hotline for technical assistance

- Extensive spare parts inventory for rapid fulfillment

- Preventive maintenance programs to maximize uptime

- Industry-leading 10-year warranty coverage

Advanced Features for Enhanced Safety

Beyond basic tote transport, modern conveyors offer advanced safety features:

Automated Controls

- Photo-eye sensors detect product presence and position

- Emergency stop systems provide immediate shutdown capability

- Variable speed drives adjust to production demands

- Integration with facility-wide safety systems

Ergonomic Enhancements

- Adjustable height stands position totes at optimal working levels

- Accumulation zones buffer materials between variable-speed processes

- Gentle acceleration/deceleration prevents product spillage

- Quiet operation reduces noise-related fatigue

Real-World Success Stories

Organizations across industries have successfully eliminated manual tote handling with automated conveyors:

Lift & Transfer module has 50 lb load capacity.

Electronics Manufacturing: A precision parts manufacturer implemented Dorner’s 2200 Precision Move conveyors to transport component trays between assembly stations. The system reduced repetitive movements for staff, which improved both the ergonomics for operators and positioning accuracy for robotic pick-and-place operations.

Food Distribution: A regional distributor replaced manual product handling with FlexMove flexible chain conveyors, enabling efficient routing through their facility’s complex layout. The solution reduced manual handling requirements and increased throughput for the facilities packaging line.

Medical Device Production: A pharmaceutical manufacturer deployed ERT pallet systems in their operation, maintaining sterility while automating product transport. The investment improved the manufacturer’s bottom line through reduced contamination and labor savings.

Heavy Parts Packaging: Protecting team members from strain and repetitive motion injuries is also important at Dorner. We’ve recently implemented a 2700 series conveyor in our parts picking department to transport boxed parts from the packer machine up an incline to a roller table and scale. This motion-detected conveyor automatically starts when boxes are pushed onto it, eliminating the need to continuously lift heavy boxes from one station to the next.

Moving Forward

Transitioning from manual tote handling to automated conveyors represents a significant opportunity to improve workplace safety, operational efficiency, and competitive advantage. Start by documenting your current tote handling processes, safety concerns, and production requirements, then explore available conveyor technologies using tools like Dorner’s online configurator (DTools) to design custom systems with instant CAD drawings.

Dorner’s application engineers also offer complimentary consultations to select and configure the optimal solution—most standard conveyors ship in 5 days or less!

Beyond equipment delivery, Dorner provides comprehensive support, including complete installation services, operator and maintenance training, ongoing technical assistance, extensive spare parts inventory, and preventive maintenance programs to maximize uptime. Whether you need a simple belt conveyor or a sophisticated pallet system for precision automation, the question isn’t whether to automate—it’s which solution best fits your needs. With over 50 years of conveyor innovation, Dorner helps facilities worldwide eliminate manual handling risks while optimizing material flow.

Ready to make your facility safer and more efficient? Contact Dorner’s conveyor experts today to discuss your specific application and receive a complimentary consultation—your workers and your bottom line will thank you.

For more information about automated material handling solutions, explore Dorner’s complete product portfolio or find a local distributor to see demonstrations of conveyor systems in action.